This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Case Study

HS2 –

Bridgwater Road

Background

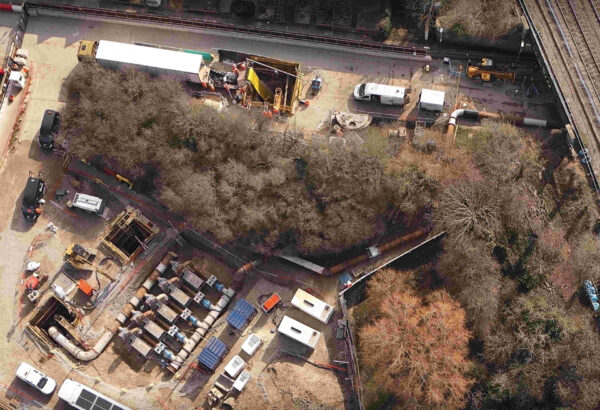

HS2 is one of the most ambitious infrastructure programmes that Britain has seen in recent years and at Clancy, we’ve been playing our part in supporting the vital project. HS2 has been assessing how existing infrastructure along the route needs to be upgraded to accommodate the new railway. This was the case at a site in Bridgwater Road in Ruislip, where the wastewater network needed to be strengthened to allow the tunnelling machine to pass underneath it. Using our expertise, we helped to advise the client on the best approach on this sewer overhaul.

Clancy was tasked with installing a specialist liner that would reinforce the sewer network against any ground movements from HS2 and increase its resilience for the future. Successful delivery was of particular significance as the sector works hard to strengthen existing infrastructure and meet the challenges of increasing capacity and extreme weather.

Solution

Clancy approached this project with the aim of delivering this major utility diversion in a way that maximised efficiency and kept the asset operational throughout.

Using our more than 65 years of experience and expertise in water and civil engineering, we decided to implement over-pumping on the site to bypass the sections being worked on while maintaining the sewer’s normal function. Once we had this in place, we began the main part of the work: the sewer relining.

Our team was determined that the best course of action was to use cured in place pipe (CIPP) lining due to its cost-effectiveness and efficiency. As a trenchless technique, CIPP is quicker and safer to install. Once the team had identified the areas which needed strengthening to mitigate ground movements from the railway, a vacuum excavator was used to create access points. The lining is inserted through these ‘keyhole’ access points and, using compressed air, inflated to adopt the shape of the pipe.

The lining’s resin is subsequently dried under UV radiation, resulting in a solid and strengthened pipe.

CIPP lining offers many benefits. However the challenge is that after it has reached the site in a refrigerated lorry, it has to be installed immediately upon arrival. Time is of the essence, with little room for error, but our team’s experience with the technology meant we were able to successfully install the lining and the get the work completed.

Benefit

The results of the project were clear. Clancy successfully reinforced the local wastewater infrastructure and ensured its future resilience as the mega-project of HS2 gets underway in the local area.

The team’s approach to innovative technology meant minimised disruption to the local community. We engaged with multiple different stakeholders to develop over-pumping routes that would take into account protecting local vegetation. With residents in mind, we also ensured through our route planning that we could keep key transport links available to the public throughout works – with both a cycle path and a footpath accessible to pedestrians.