This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Case Study

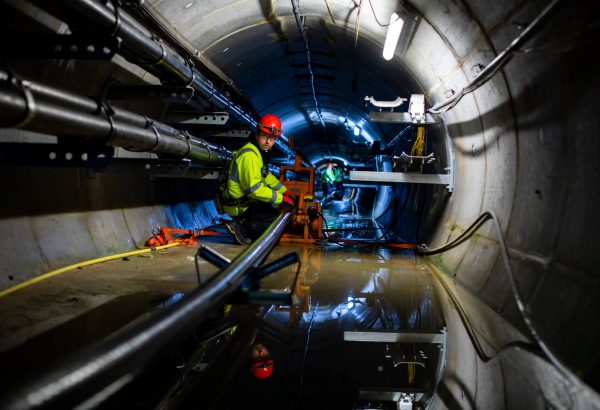

UK Power Networks – Stewart’s Road Substation Tunnel

320m

Cable tunnel

Winner

Best infrastructure project

Background

The Battersea Power Station forms part of the wider £9bn Nine Elms regeneration project on the south bank of the River Thames. The 42-acre former industrial brownfield site offers a vibrant new neighbourhood and business quarter for London, serviced by an extension to the Northern Line. With expected energy demand increasing, Clancy were bought on board to provide a 300m cable spur tunnel to link a new substation with the existing deep cable tunnel. This provides the required 40MVA load capacity to the iconic development.

Maintaining power throughout was a key consideration. The team’s innovative approach made the Battersea Cable Tunnel project the first time that UK Power Networks had been able to extend a tunnel network without needing any power outages.

Martin McGovern

Associate Director

Solution

Construction in central London requires navigating around the existing maze of infrastructure. Automated monitoring ensured that there was no risk to existing Thames Water and Network Rail assets, and bespoke internal steel strapping was used to support the existing cable tunnel, reducing risk of potential cable damage.

The project also required precise, careful work around live cables. Clancy stopped the TBM boring just 4m away from 132kV cables, after which hand mining formed the connection between the new and old cable tunnels.

Benefit

Clancy’s efforts have bought life back to a once-derelict part of London. The project was a huge success: 118,520 hours were worked without injury and the project won numerous awards.

Clancy strive for as little disruption to local communities as possible. Clancy innovatively chose to begin work for the Tunnel Boring Machine (TBM) and substation within a specifically sound-deadened existing warehouse to reduce noise disturbance. This enabled 24-hour operations and so increased the speed of the project.

A local school was also involved in the project, who chose to name the TBM after space scientist Maggie Aderin-Pocock.