This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Case Study

Anglian Water WRN – BlueLight technology

Innovative technology for trenchless repairs

Sewer and storm pipe deterioration has become a significant capital expenditure for water companies due to the risk of major infrastructure failure. Repairing these assets when they do fail can be high in cost and cause disruption. Clancy is always looking for new technologies and innovative techniques to enhance ways of working – both to minimise environmental impact and to be as efficient as possible.

The Water Recycling Network Alliance, part of the Anglian Water Alliance framework, is responsible for all capital drainage and rainwater catchment rehabilitation across the Anglian network. The Clancy lining team has been investing in skills and equipment which allow it to drive efficiency, improve health and safety and minimise disruption on site.

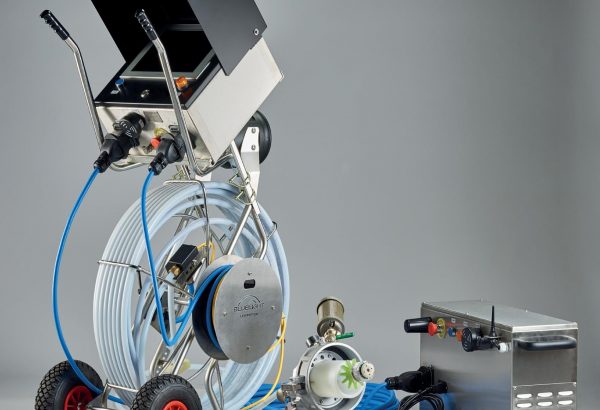

Clancy approached BlueLight GMBH looking for system that would be capable of carrying out re-lining repairs to the wastewater network with minimal risk. Clancy was the second company in the UK to invest in the full system. The equipment was originally designed and developed by Per-Aarsleff, who spent ten years testing the equipment’s capabilities before it was available to the market.

An efficient system

The technology has brought significant benefits to site and is now being rolled out for a number of jobs across the Anglian Water framework, as Steve explains: “BlueLight technology is fast to install and to cure, and easily transported in a small van, which means we can set up in tight or restricted areas with minimal disruption. We’ve worked closely with our BlueLight partners in the UK to further

develop our knowledge and test new materials. For the same cost of digging down to a damaged section of pipe, we can now repair the entire length of it, and do so in a way that is faster and reduces the risk of service strikes.”

Project photos

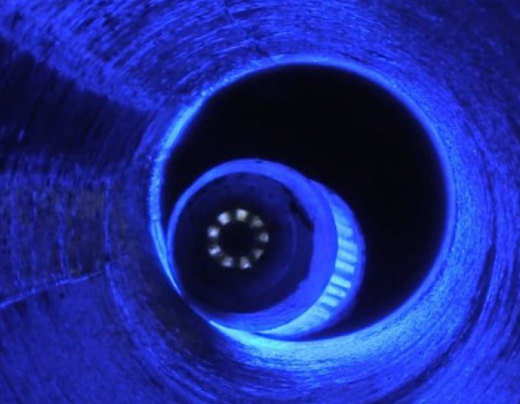

The technology in action

Anglian Water approached Clancy to find a solution to a critical sewer system in Cottenham, Cambridgeshire, which was at risk of failing and causing disruption in the area. We worked closely with Clancy’s BlueLight UK & German partners to trial its new pull in place PAA-G glass fibre liners to reinforce the deteriorated sewers in the area. Steve says: “This repair was the first of its kind in the UK. The liner is made up of vinylester resin, which contains no styrene and therefore does not produce an odour. The lower curing temperature of the BlueLight LED system and its faster curing time meant the project was completed ahead of schedule. It’s been a real game changer and we’re excited by the potential of this technology and the impact it’s already having on the majority of our wastewater repair work with Anglian Water.”